Pharmaceutical supply planning plays a critical role in ensuring the availability of life-saving medications while minimizing waste and optimizing efficiency. However, traditional approaches relying on spreadsheets and manual calculations are proving to be insufficient in meeting the complex demands of the industry. This comes true especially for CDMO´s and other 3rd party manufacturers that are having to deal with increased complexity in their manufacturing setups. Fortunately, advancements in technology have brought forth innovative solutions that are transforming the landscape of pharmaceutical manufacturing, where Supply Planning lies at the heart of everything.

In this article, we explore the key advantages of having an AI powered Supply Plan that provides real-time visual feedback on demand versus manufacturing capacity. The Plaio Coplanner leverages AI-assisted calculations to optimize supply plan calculations based on manufacturing capacity (CMO or own) taking into account all relevant variables, such as lead times and MOQ´s, embracing forward-looking capacity planning.

Gone are the days of rigid, one-size-fits-all planning approaches. Visual planning solutions empower pharmaceutical manufacturers to configure their planning processes according to their unique requirements. With intuitive interfaces and drag-and-drop functionality, planners can easily customize workflows, defining the stages, dependencies, and rules that govern their demand and supply planning, as well as purchase planning. This flexibility allows for seamless integration with existing systems and the ability to adapt rapidly to changing market dynamics.

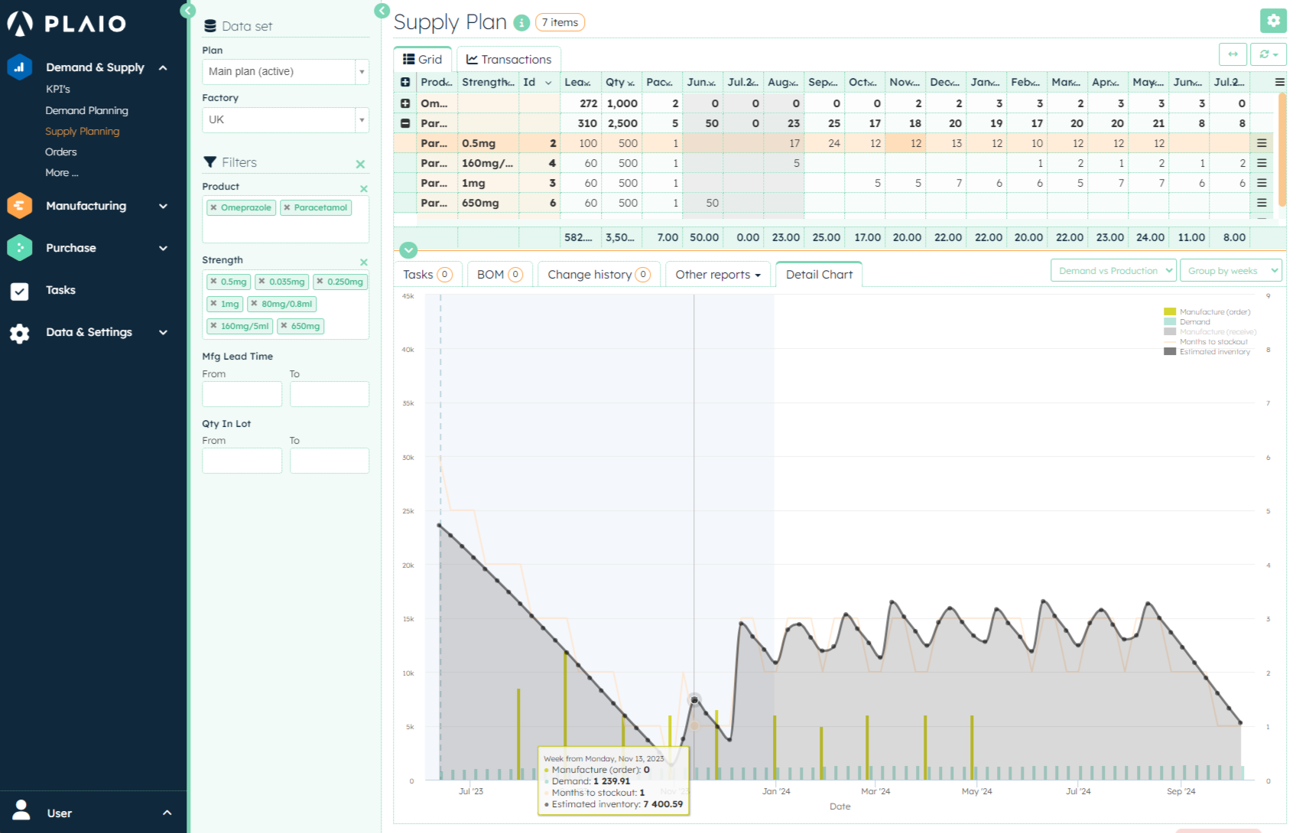

The integration of visual feedback in pharmaceutical supply planning provides a clear and intuitive representation of the demand versus manufacturing requirements. Through interactive dashboards and data visualization tools, supply planners gain real-time insights into production demands, allowing them to identify potential bottlenecks, forecast shortages, and allocate resources effectively. This visual approach enables proactive decision-making, minimizing the risk of stockouts or excess inventory, and optimizing overall supply chain performance.

Harnessing the power of artificial intelligence (AI), the Plaio Coplanner is revolutionizing pharmaceutical supply planning by automating complex calculations. With the Plaio Coplanner's AI-assisted capabilities, planners can streamline and optimize production schedules, inventory levels, and replenishment strategies. By leveraging historical data, market trends, and machine learning algorithms, the Plaio Coplanner assists in making accurate predictions, reducing manual errors, and facilitating agile decision-making in the face of changing market dynamics.

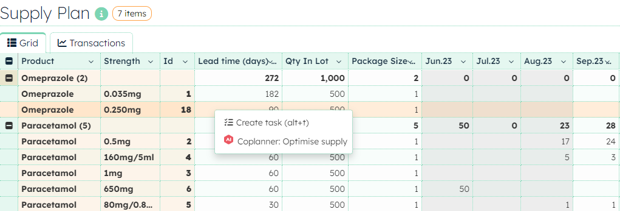

Optimising Supply with PLAIO Coplanner

Contract Manufacturing Organizations (CMOs) play a crucial role in the pharmaceutical supply chain. However, effectively managing CMO relationships can be challenging, especially when balancing optimal purchase frequencies with CMOs' minimum order quantities (MOQs). Leveraging advanced supply planning solutions, pharmaceutical companies can analyze purchase patterns, demand forecasts, and MOQ requirements to determine the optimal purchase frequency. This ensures that inventory levels are aligned with demand, minimizing inventory holding costs while maintaining a reliable supply.

Capacity planning is a key element in pharmaceutical supply planning, as it ensures that production capabilities align with market demands. Traditional approaches often focus on historical data and short-term projections, leading to reactive decision-making. However, with forward-looking capacity planning, pharmaceutical companies can adopt a proactive approach by considering long-term growth plans, anticipated product launches, and market trends. By incorporating sophisticated modeling techniques and scenario analysis, supply planners can identify potential capacity constraints, optimize resource allocation, and make strategic investments to meet future demands.

Orchestrating the optimal capacity planning is crucial for pharmaceutical manufacturers to meet market demands while maximizing resource utilization. Visual planning solutions bring this orchestration to life by providing dedicated features for capacity planning and supporting Sales and Operations Planning (S&OP) processes. Planners can accurately assess production capabilities, allocate resources efficiently, and identify potential bottlenecks or excess capacity. This ensures a harmonious balance between demand and supply, optimizing efficiency and reducing costs.

PLAIO Supply Plan Module

The pharmaceutical industry is witnessing a transformation in supply planning with the advent of new technologies and innovative solutions. Visual feedback of demand versus manufacturing needs, AI-assisted calculations through the Plaio Coplanner and forward-looking capacity planning are revolutionizing the way pharmaceutical companies manage their supply chains.

By embracing these advancements, pharmaceutical manufacturers can enhance operational efficiency, reduce costs, minimize supply disruptions, and ultimately ensure the availability of critical medications for patients worldwide.

It is crucial for industry stakeholders to embrace these advancements and leverage technology to unlock the full potential of pharmaceutical supply planning.

To enhance your experience on our site and to analyze traffic, we use cookies. By clicking "Accept All," you agree to the storing of cookies on your device for analytics purposes. You can manage your settings or learn more in our Privacy Policy.

We use cookies to improve your browsing experience and analyze how our website is used. These cookies allow us to understand trends, monitor website traffic, and gather insights to make the site better for you.

We respect your privacy and are committed to transparent data usage.

Necessary Cookies: These ensure that the website functions properly.

Analytics Cookies: These help us track site traffic, user behavior, and performance metrics. The data collected is anonymous and allows us to continuously optimize the site.

Preferences Cookies: We may use cookies to remember your preferences and tailor your experience.

Marketing Cookies: We may use cookies for marketing purposes.

By clicking "Accept All," you consent to the use of all cookies. If you prefer, you can customize your choices and opt out of certain cookies. You can learn more about how we handle data and cookies in our Privacy Policy.